FE65H1H-U GMCC REFRIGERATION COMPRESSOR

FE65H1H-U Reciprocating Compressor

Nominal voltage limits: 115V/60Hz

Refrigerant: R134a

Operating Back Pressure: L.B.P

Cooling Type: Natural cooling

Restriction Device: Capillary pipe

Motor Type: RSIR

Running capacitance (μF): None

International Delivery (Outside of Trinidad & Tobago)

We deliver worldwide via courier or freight forwarder.

Most orders are shipped with UPS or DHL. If you have an account with a specified courier, please let us know your account details when you are placing the order.

For larger orders, we ship via ocean freight with our freight forwarder.

Delivery within Trinidad & Tobago)

All orders within Trinidad & Tobago will be delivered either by our in-house delivery service or via TTPost. Delivery is usually fulfilled locally within 0-2 business days.

For orders placed after 7am, delivery will be fulfilled on the following business day.

For orders placed before 7am, it’s possible that we can accommodate same-day delivery as our driver usually leaves our warehouse for daily deliveries between 7-8am.

If you require an item urgently, do let us know. We will do our best to accommodate your needs.

Returns

We do not facilitate international returns.

For local returns, only items returned within 14 days of their original shipment date in same as new condition and in the original packaging will be eligible for a refund or store credit with the original receipt. Restocking & sanitization fees will be charged upon return.

Help

Give us a shout if you have any other questions and/or concerns.

Email: [email protected]

Phone:1(868)-658-1910 / 1911 / 2010

2. Compressor Design Parameter

| Refrigerant Oil Type | Synthetic ester oil |

| Refrigerant Oil Viscosity | 9.9mm2/S (40℃) |

| Refrigerant Oil density | 0.95 g/ml (15℃) |

| Refrigerant Oil Grade | ISO 10 |

| Net mass ( oil included ) | 8.2±0.4kg |

| Discharge tube (Inner Diameter) | Φ4.2±0.1mm |

| Suction tube (Inner Diameter) | Φ6.2±0.1mm |

| Process Tube (Inner Diameter) | Φ6.2±0.1mm |

| Material for Tube | Copper |

| Shielding Gas | Nitrogen |

| Residual impurities | ≤50mg |

| Residual moisture ( oil included ) | ≤100mg |

| Starting Ability | 98V [0.50/0.50 Mpa(abs)](25°C) |

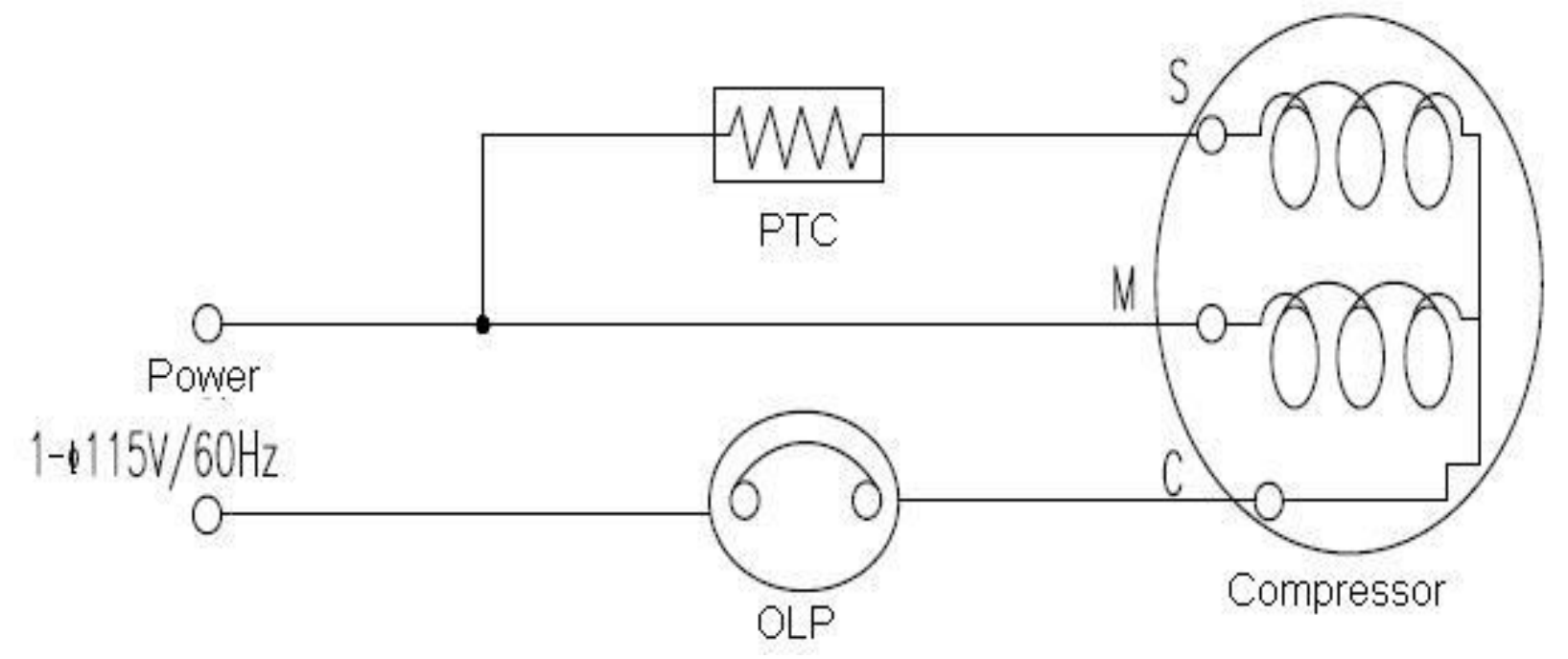

3. Electric Characteristic

| Wiring Diagram(RSIR) | As following |

| Insulation grade | “E” |

| 20℃ Main Winding resistance | 3.14±7%Ω(Aluminum) |

| 20℃ Aux Winding resistance | 7.33±7%Ω(Aluminum) |

| Security | UL 60335-1 / UL 60335-2-34 |

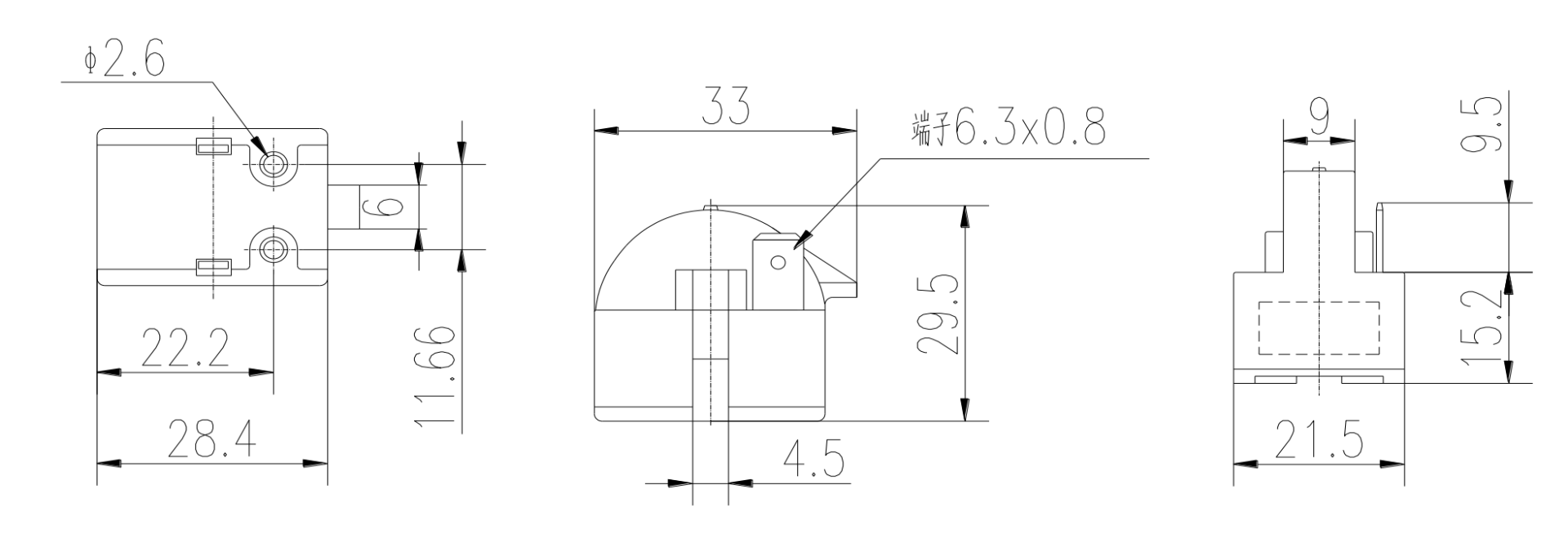

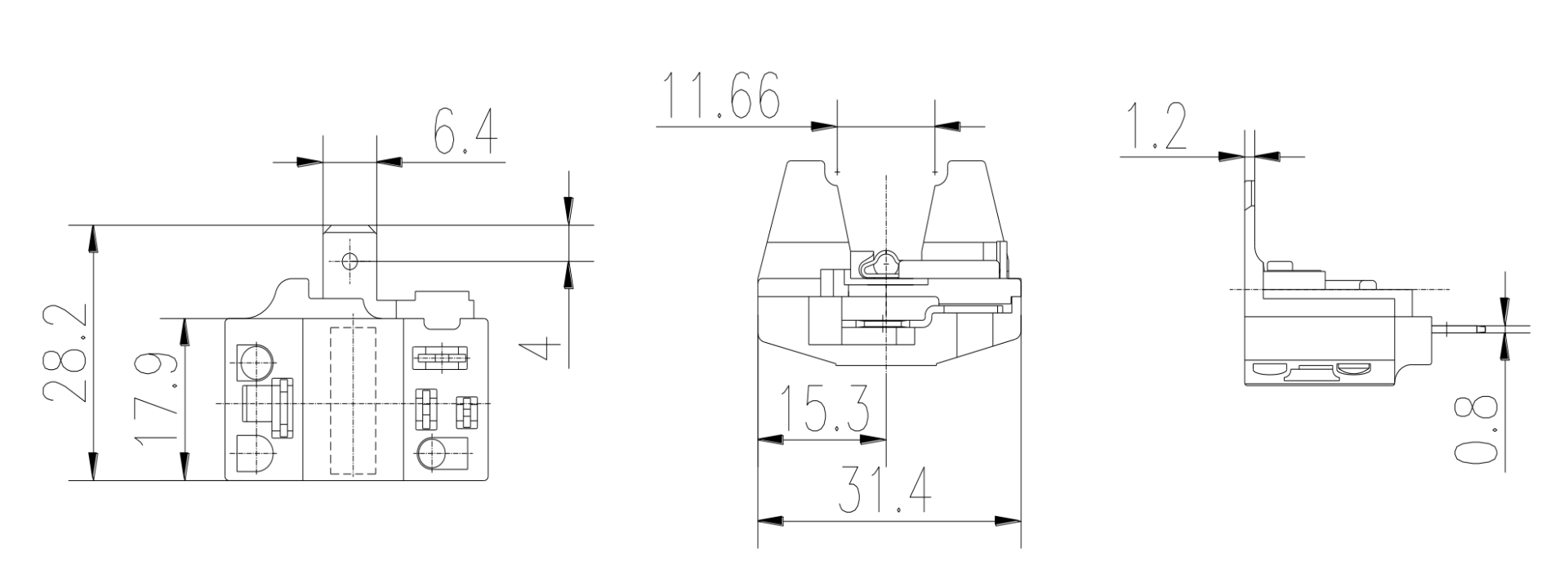

1)Electric wiring diagram(RSIR)

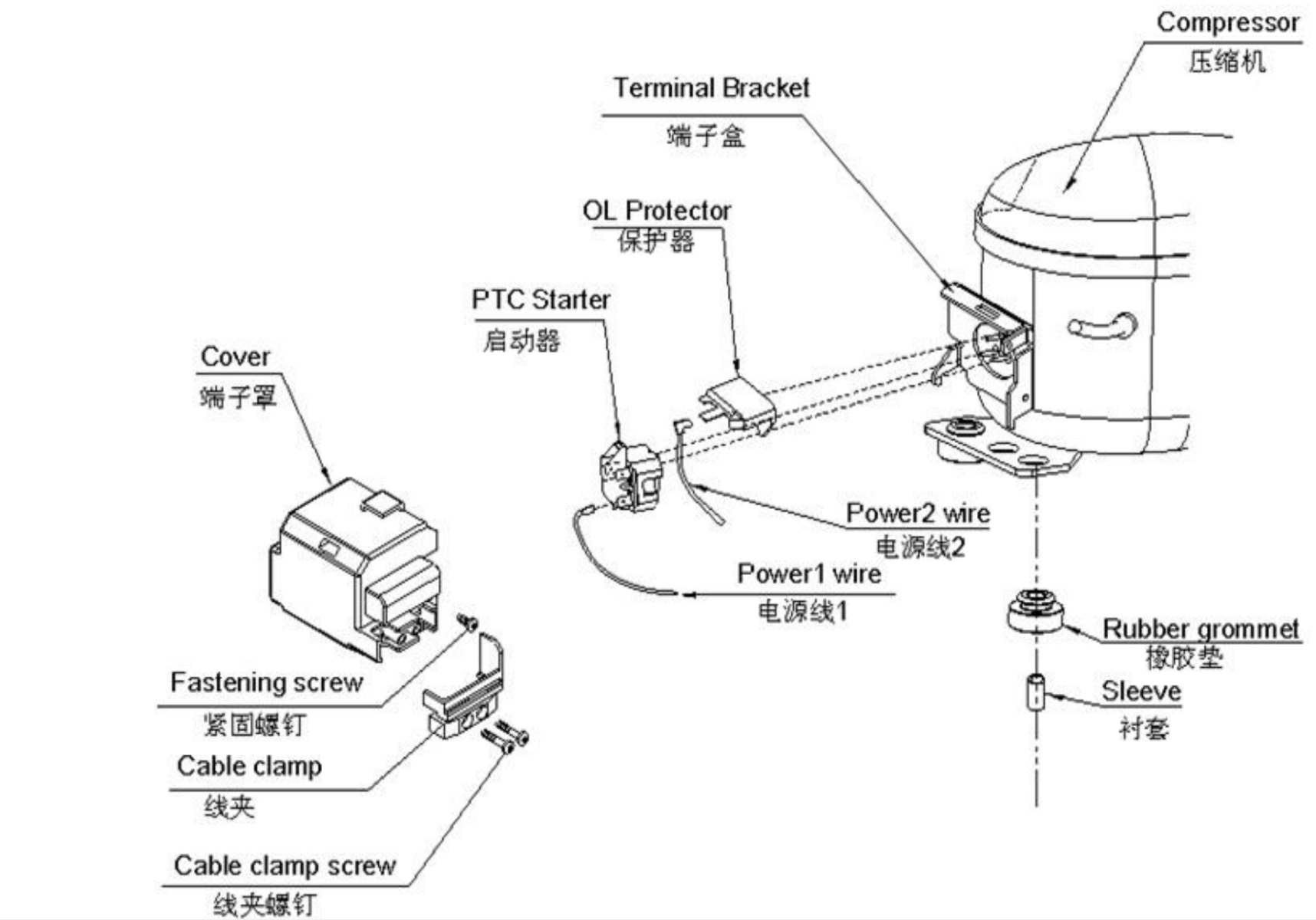

2)Accessory assembly diagram (RSIR)

4. Component Specification

| Parts Name | Specification | Supplier |

| Starter | QP2-4R7 | Star Shuaier |

| Protector | DRB34T61A1 | Star Shuaier |

4.1 Starter Performance Parameters

| Compressor Model | FE59E1M | |

| Starter startor | Specification | QP2-4R7 |

| Normal resistance Ω | 4.7±20% | |

| Action time S | 0.2~1.4 | |

| Release time S | <80 | |

| Maximum voltage V | 180 | |

| Maximum current A | 12 | |

| Note: Assembly force ≤98N, uninstall force ≥25N,Flame retardant grade:UL94V-0. | ||

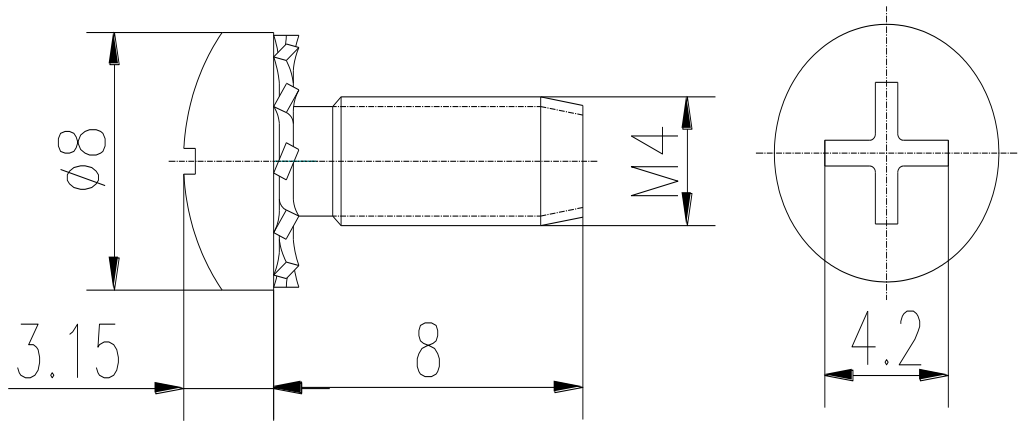

The following figure

4.2、Protector Performance Parameters

| Compressor model | FE65H1H-U | |

| OL protector | Specification | DRB34T61A1 |

| Action current(25℃) A | 12.3 | |

| Action time S | 10±5 | |

| Release time S | 30-360S | |

| Operating temperature ℃ | 140±5 | |

| Reset temperature ℃ | 61±9 | |

| Minimum working current(71℃) A | 3.24±20% | |

| Note: Assembly force ≤98N, uninstall force ≥25N,Flame retardant grade:UL94V-0. | ||

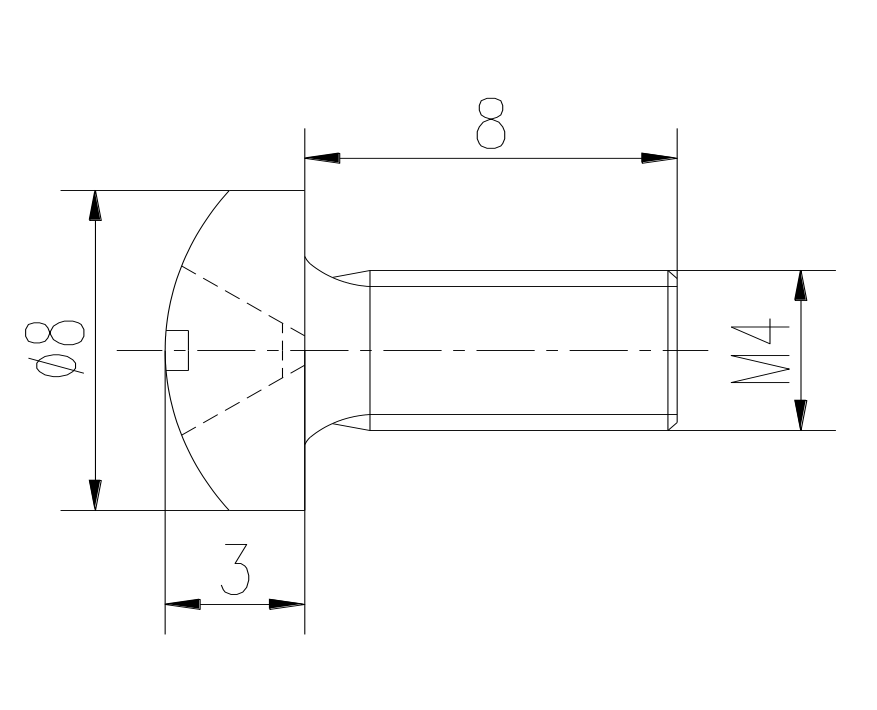

The following figure

5. Performance Parameters

| Displacement (cm3 ) |

Capacity (W)≥95% |

Input power(W)≤115% |

Curren(A)≤110% | COP(W/W)≥95% | Sound level[dB(A)] | Vibration(m/s2 ) |

| 6.5 | 215 | 153.6 | 1.9 | 1.40 | ≤43 | ≤0.5 |

ASHRAE Working Condition for Test:

Evaporating temperature:-23.3℃ Ambient temperature:32.2℃

Condensation temperature:54.4℃ Suction temperature:32.2℃

Sub cooling temperature:32.2℃ Test voltage: 115V/60Hz

6. Packing storage and transportation

| Amount | 96 pcs/pallet and 2112pcs/container(with accessories) |

| Vehicle | Train Or Automobile |

| Stacking Capacity | 2 |

| G.W. | 817.2 |

| N.W. | 787.2 |

| Cubic Measure m3 | 1.04 |

| Dimensions L×W×H(mm) | 1100×920×1030 |

| Packaged Component | Buttplate, up cover board, foam baffle, plastic cage, packing tape |

| Amount | Keep compressor normal upright (a little while before compressor to be installed in refrigerator) |

Cautions

| Ambient temperature | -5~43℃ |

| Evaporating temperature | -35~-10℃ |

| Voltage range | 98-127V |

| Max. pumping pressure | 0.92 MPa |

| Max. condensing temperature | 65℃ |

| Max. winding temperature | 120℃ |

| Max. Shell temperature | 90℃ |

| Max. discharge temperature | 120℃ |

| Allow the injectionrate of refrigerant(kg) | <0.1 |

| Flood back amount of refrigerant | No flood back |

| Intermittent operation item | ON:> 5 minutes,OFF:> 5 minutes or more |

| Operation cycle times | > 200,000 |

| Activate compress at refrigerant Soaking | No noises after starting |

| Angle of slope | within 5° |

| Pressure difference at start-up | The pressure should be balanced at the high-pressure and lowpressure sides at start-up. If pressure is not balanced, you need to check compressor's starting performance. |

Remarks:

- Please do not exert compel lent bending force. At the moment when compressor start, run or stop, the

bending force exerted on tubes should meet the requirement as following:

Start or stop ≤29.4N/mm2

Run ≤19.6N/mm2 - Please ensure the uprightness of compressors in transportation. Avoid being convert, bumping and

vibrating; - Avoid high-voltage test and start test on compressor while in the vacuum state;

- Please have compressor connected to the refrigeration system within 5 minutes after removing the rubber plug.

Avoid the entry of dust and humidity into the compressor. - Avoid over-filling refrigerant

- If refrigerant can not be merged with refrigeration oil, please do not start running the compressor. Or the

components would be over-attrited; - Avoid wrongly-connecting external power supply line so that compressor to be scrapped.

- Compressors must be matched to components, such as starter and protector, appointed by AMCC.

- The wiring in terminal cover must be with high heat resistance property

- There must be no chloric draffy in refrigeration system, such as rust remover and abluent. Organics limited is

below 100mg - Please store compressors in ventilated and dry environment. Avoid the entry of humidity into compressor.

- The compressors should not be laid idle for 6 months. If not, please check that weather there is enough dry

N2 in compressors.

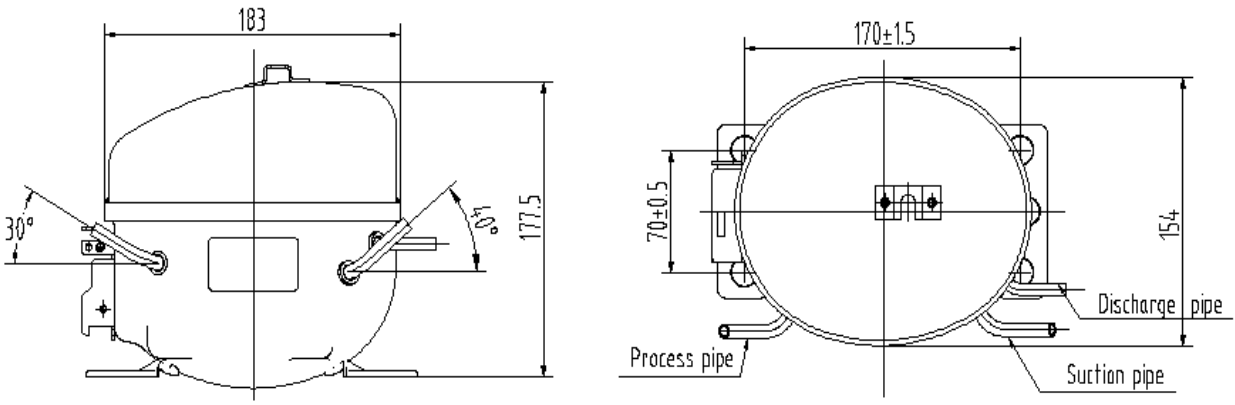

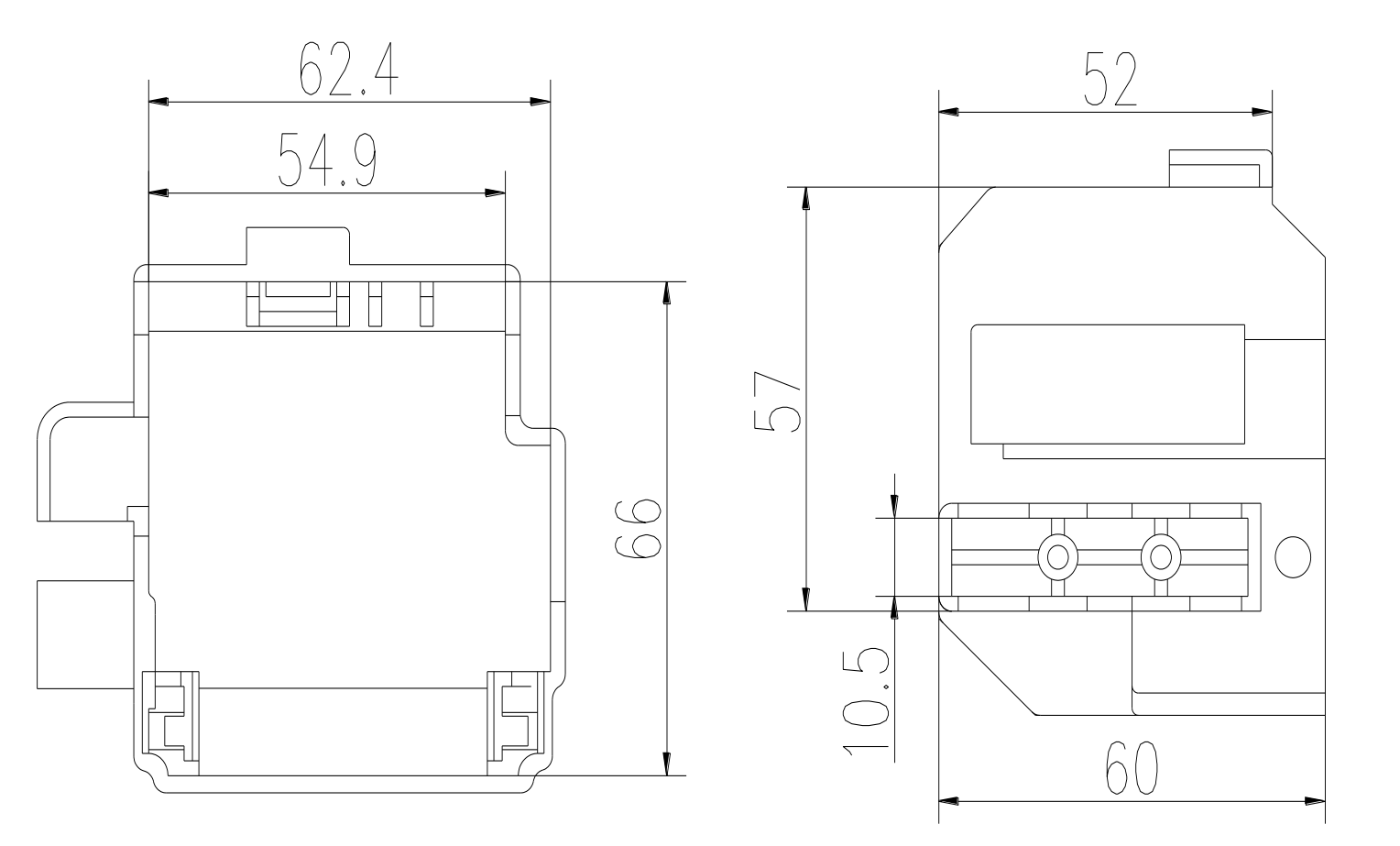

8. Product Drawings

8.1 Product Outline Drawing

8.2 Terminal cover

8.3 Cable clamp

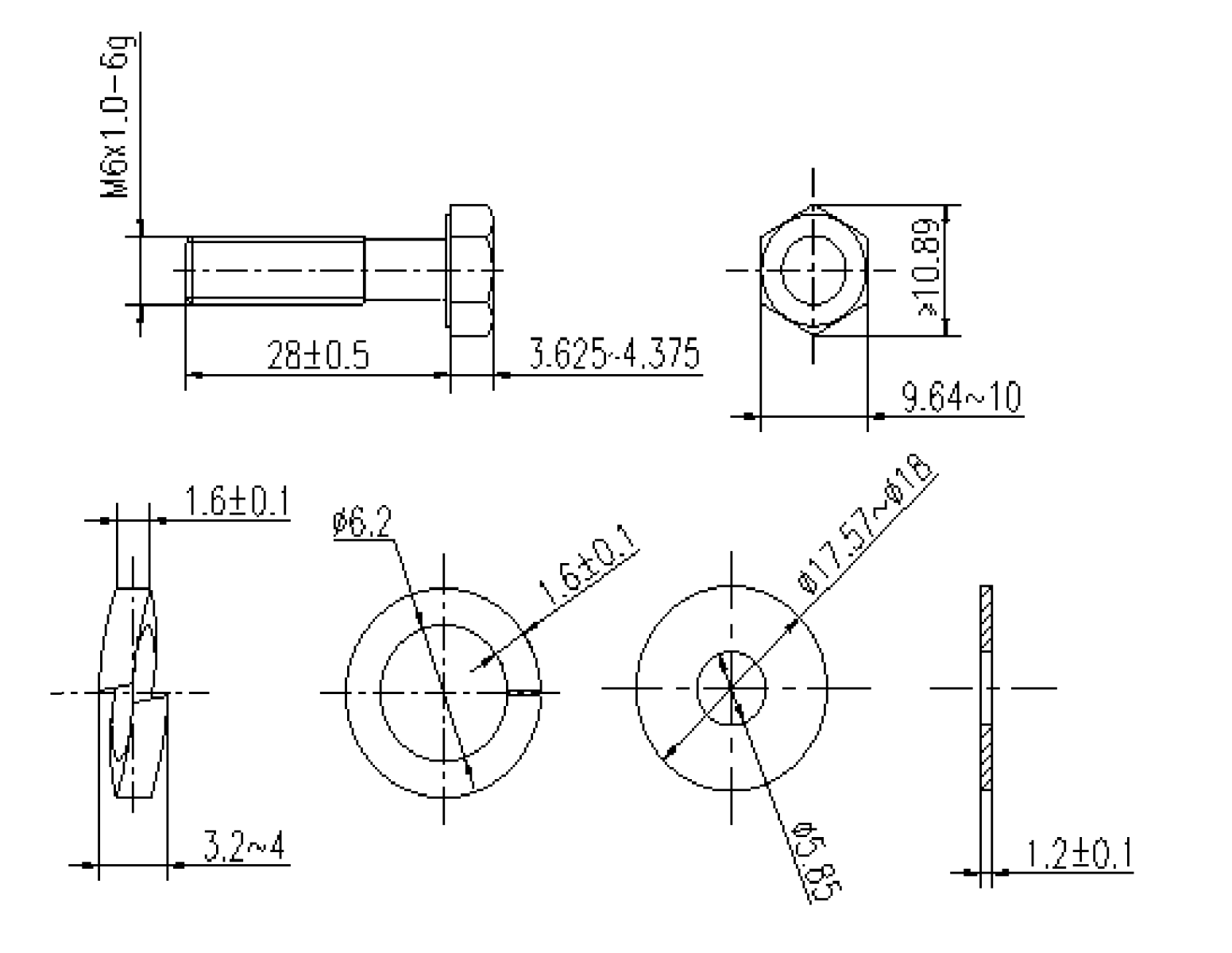

8.4 Tightening screw

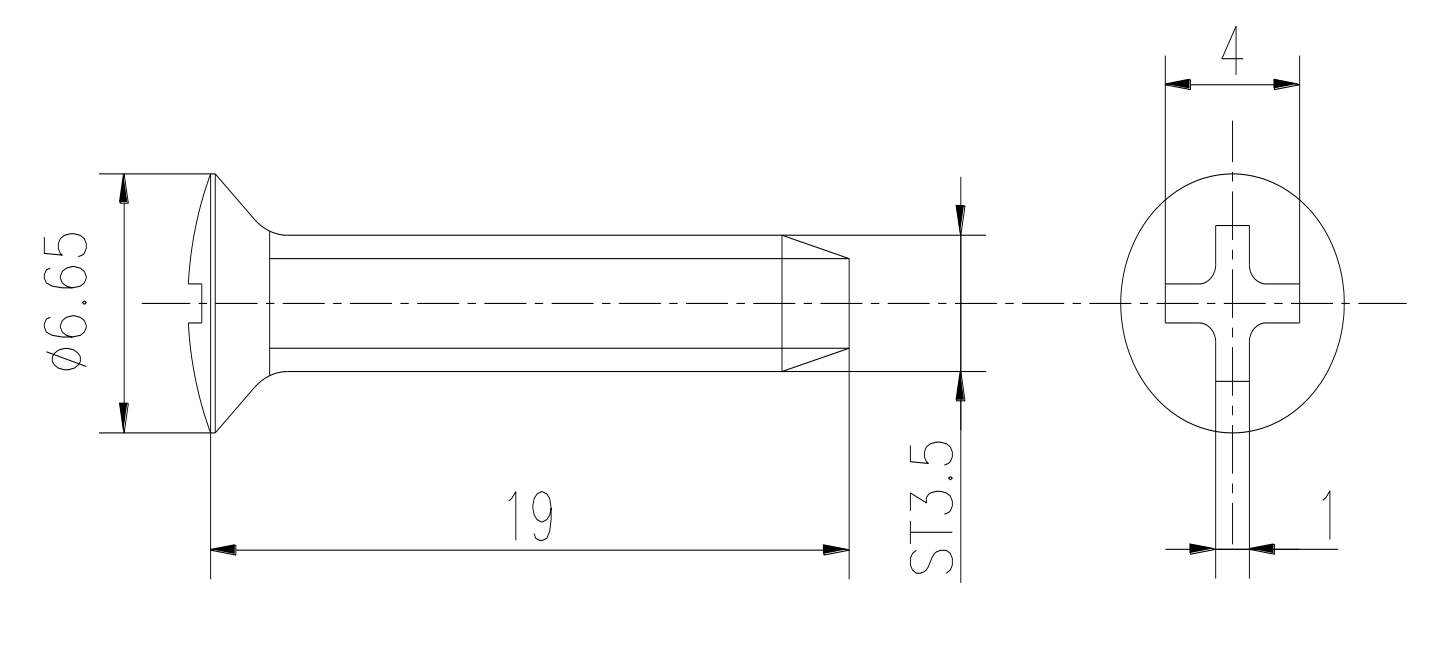

8.5 Cable clamp screw

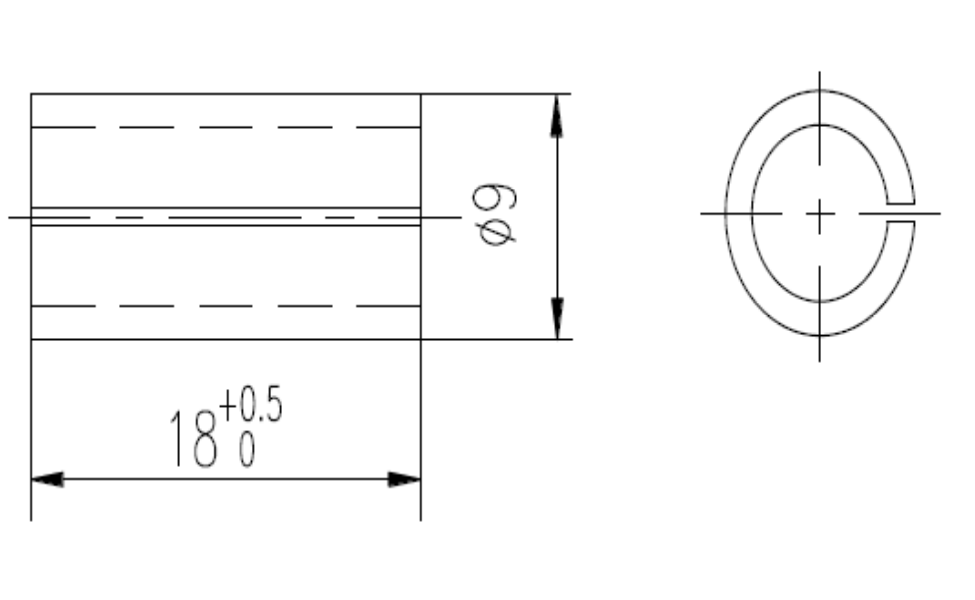

8.6 Anti-vibration sleeve

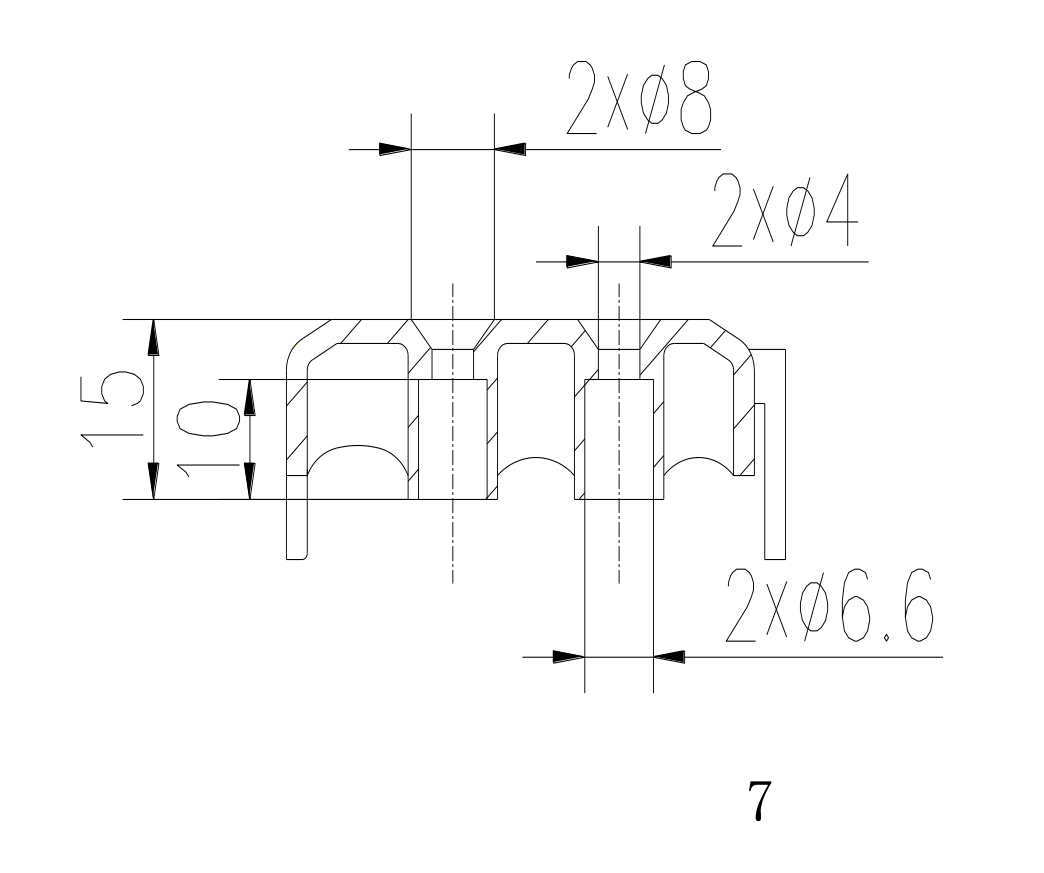

8.7 Rubber

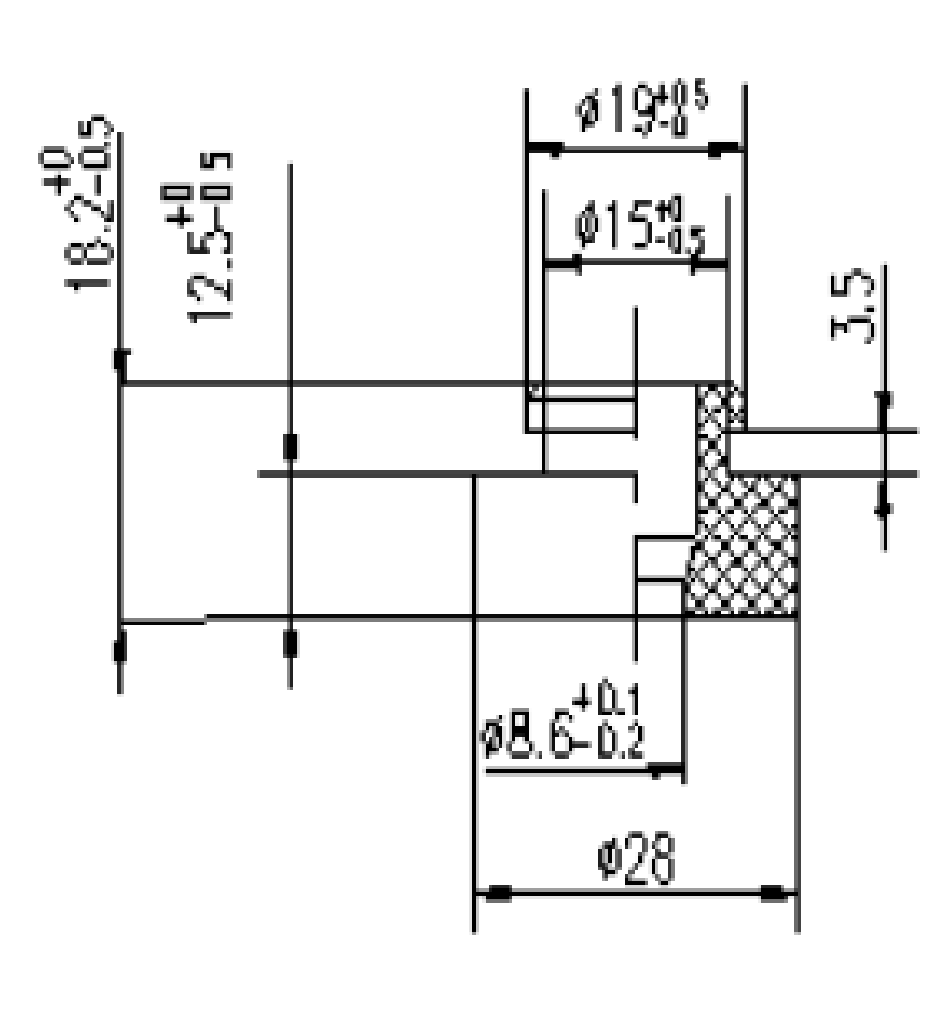

8.8 Mounting bolt assembly

8.9 Ground screw

9. Product Certification

| Number | Name | Type | Certification type |

Certificate no. | Maker |

| 1 | Compressor | FE65H1H-U | UL | SA32976 | Anhui meizhi |

| 2 | Starter | QP2-4R7 | UL | E232371 | Star Shuaier |

| 3 | Protector | DRB34T61A1 | UL | E213160 | Star Shuaier |

10. Delivery List for Components

| Number | Name | Specification | Amount | Remark |

| 1 | Compressor | FE65H1H-U | 1 | |

| 2 | Starter | QP2-4R7 | 1 | |

| 3 | Protector | DRB34T61A1 | 1 | |

| 4 | Terminal cover |

1 | ||

| 5 | Cable clamp assembly |

1 | ||

| 6 | Tighting screw | 1 | ||

| 7 | Anti-vibration sleeve |

4 | ||

| 8 | Mounting bolt assembly |

4 | ||

| 9 | Rubber | H=18 | 4 | Pre-assembly |

| 10 | Ground screw | 1 |

Remark:

Each component is independently packaged instead of installed on compressor. If there is no figure in

AMOUNT column, the corresponding component is not included for this compressor type.

11. Environmental Requirement

Regarding compressor and fitting

1、PAHs request :PAHs(Ⅱ):BaP content <1ppm、16 kind of PAH(EPA) total quantity<10ppm;

2、REACH laws and regulations request:SVHC the limit is smaller than 1000ppm;

3、The phthalic acid salt (fat) requests :18 item of deleterious substance limits request are smaller than 1000

ppm

| Brand | GMCC |

|---|