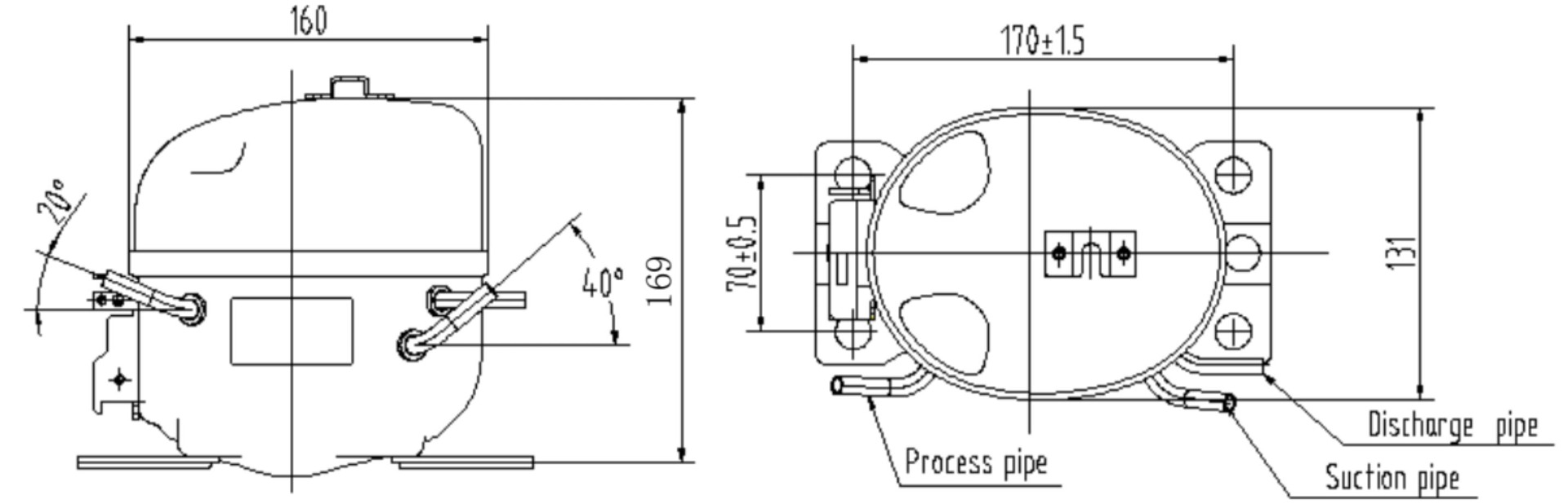

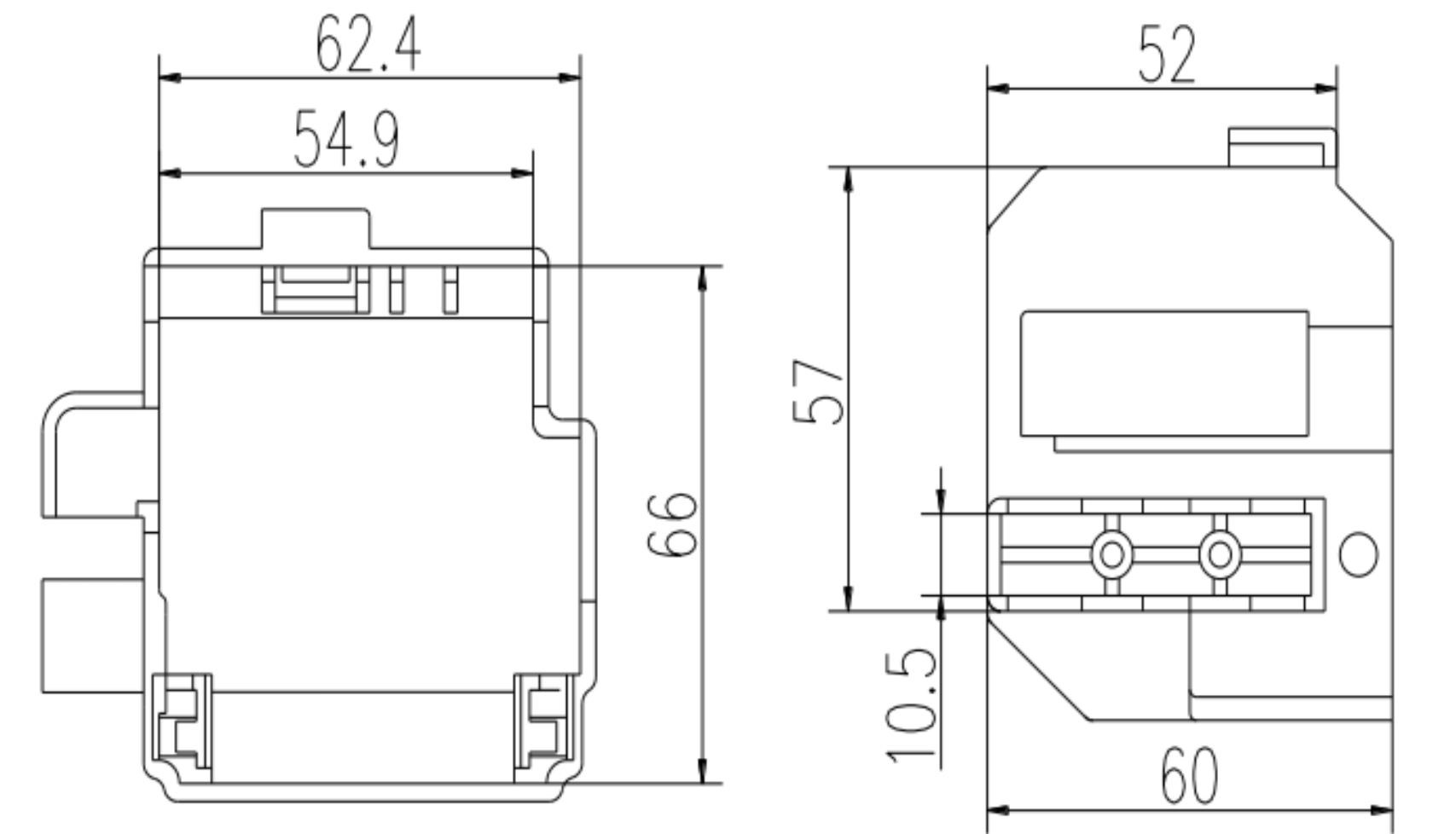

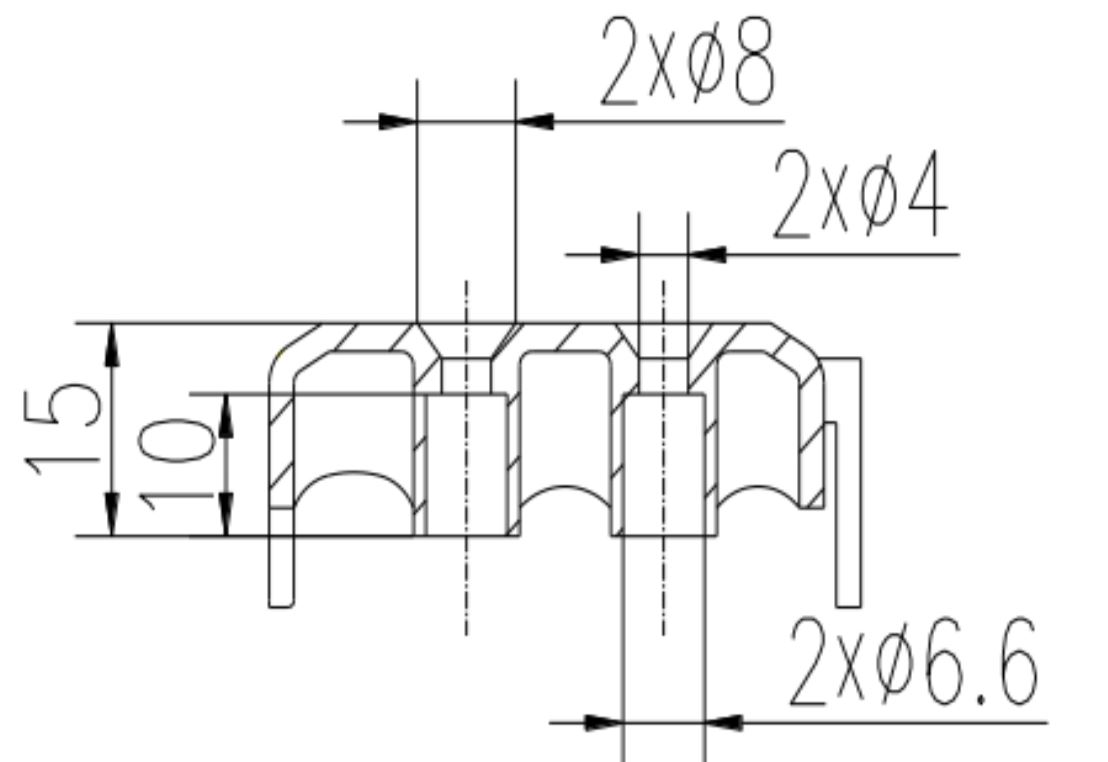

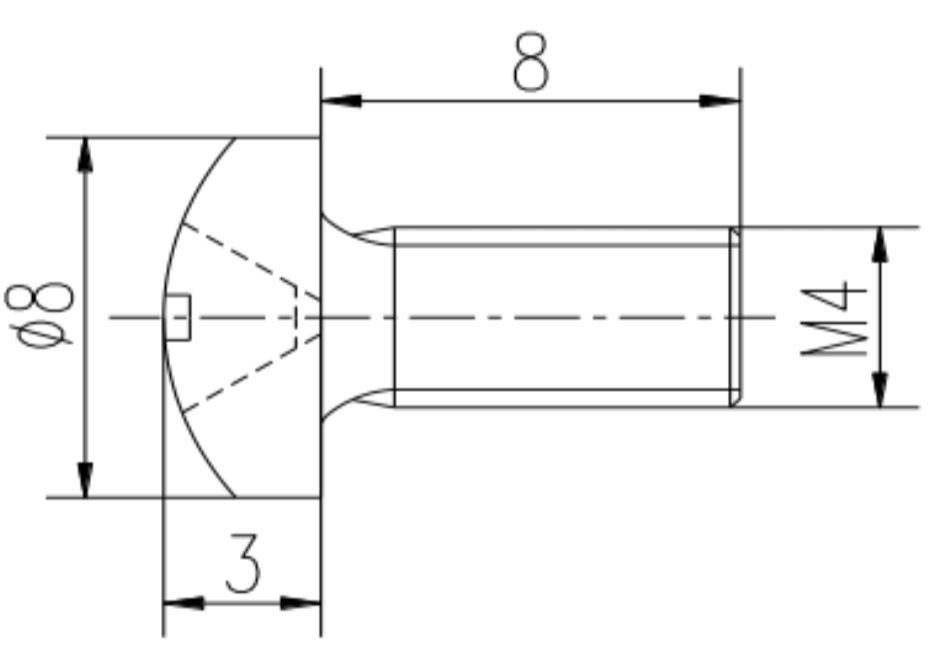

FE45E1M-U GMCC REFRIGERATION COMPRESSOR

GMCC FE45E1M-U REFRIGERATION COMPRESSOR

Nominal voltage limits: 115V/60Hz

Refrigerant: R134a

Operating Back Pressure: L.B.P

Cooling Type: Natural cooling

Restriction Device: Capillary pipe

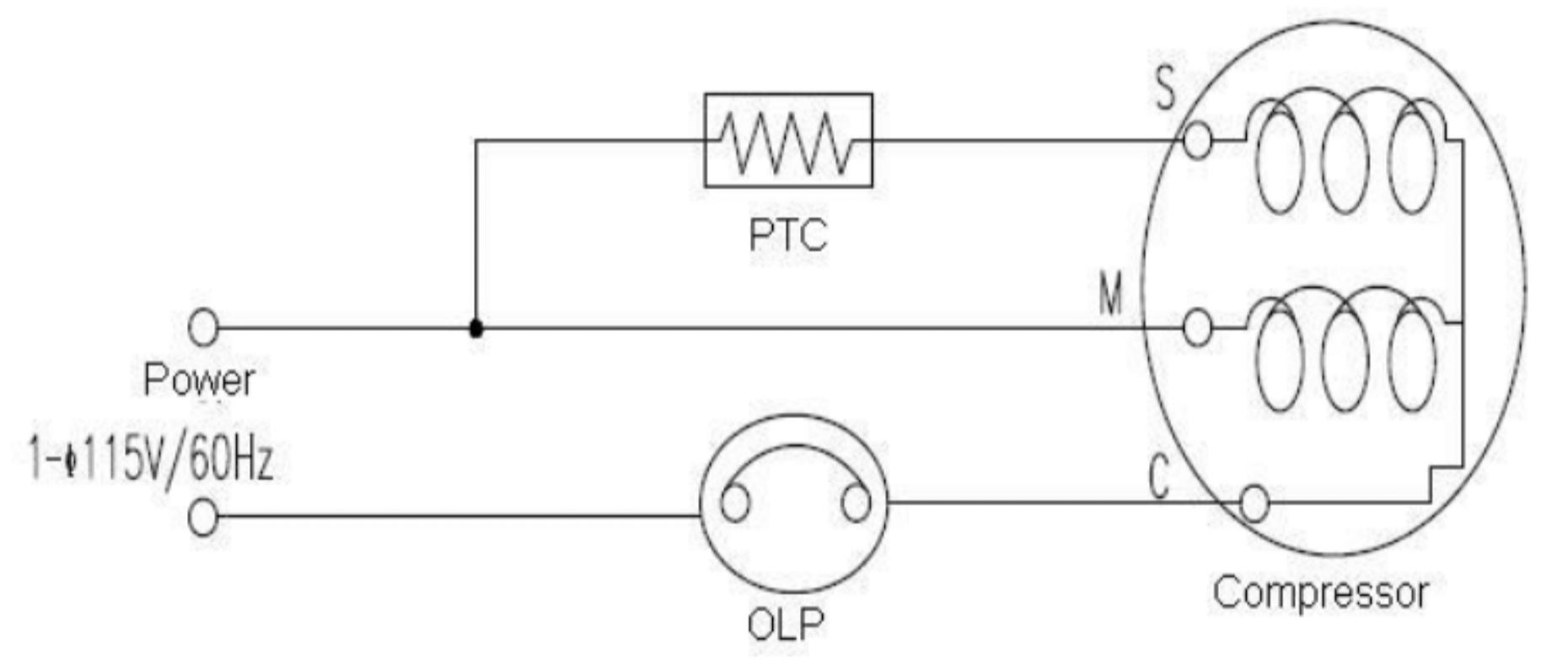

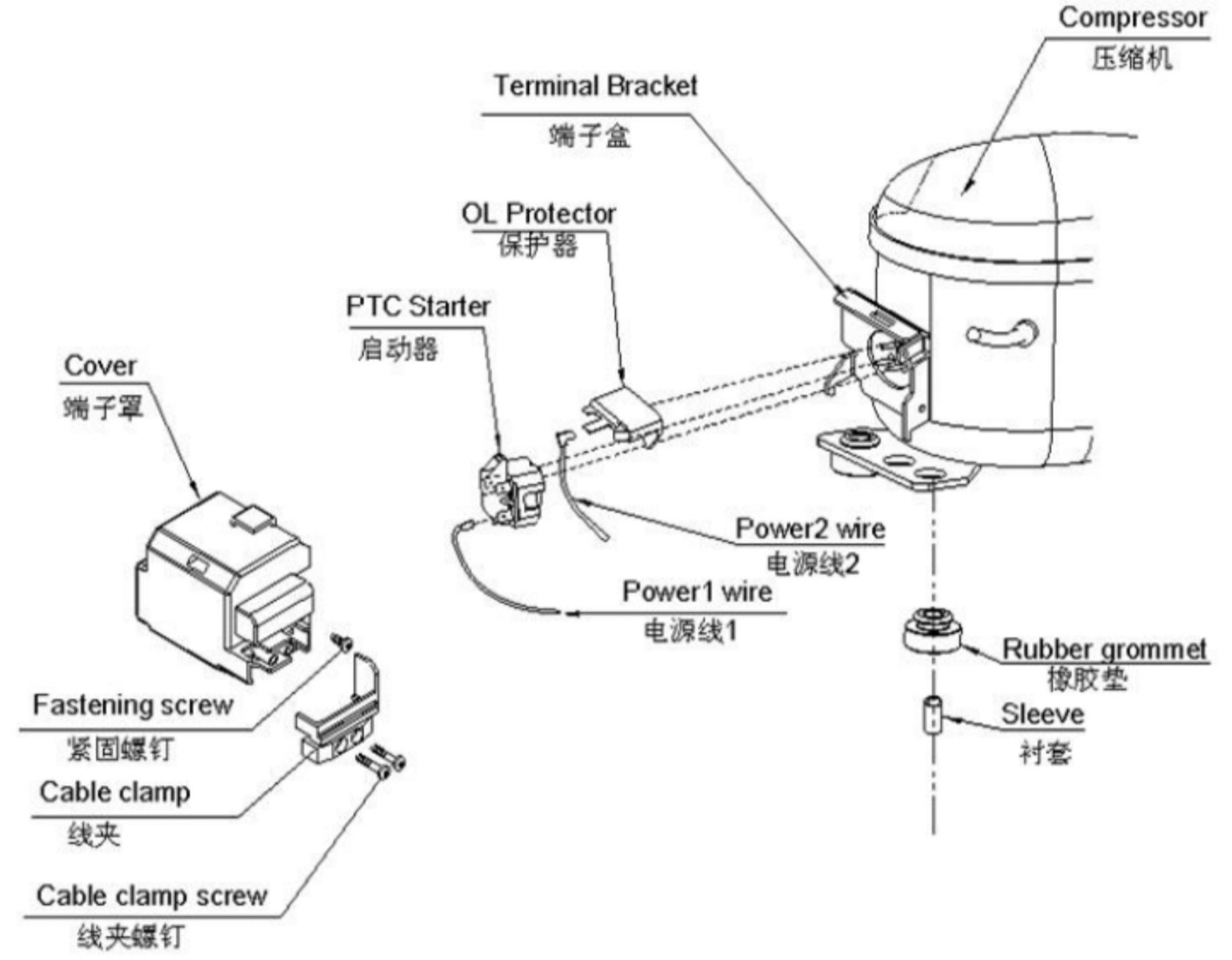

Motor Type: RSIR

Running capacitance (uF): None

International Delivery (Outside of Trinidad & Tobago)

We deliver worldwide via courier or freight forwarder.

Most orders are shipped with UPS or DHL. If you have an account with a specified courier, please let us know your account details when you are placing the order.

For larger orders, we ship via ocean freight with our freight forwarder.

Delivery within Trinidad & Tobago)

All orders within Trinidad & Tobago will be delivered either by our in-house delivery service or via TTPost. Delivery is usually fulfilled locally within 0-2 business days.

For orders placed after 7am, delivery will be fulfilled on the following business day.

For orders placed before 7am, it’s possible that we can accommodate same-day delivery as our driver usually leaves our warehouse for daily deliveries between 7-8am.

If you require an item urgently, do let us know. We will do our best to accommodate your needs.

Returns

We do not facilitate international returns.

For local returns, only items returned within 14 days of their original shipment date in same as new condition and in the original packaging will be eligible for a refund or store credit with the original receipt. Restocking & sanitization fees will be charged upon return.

Help

Give us a shout if you have any other questions and/or concerns.

Email: [email protected]

Phone:1(868)-658-1910 / 1911 / 2010